- Wölfel Blog

- Artificial Intelligence in SMEs – AI Building Blocks for Product and Process Optimization

Artificial Intelligence in SMEs – AI Building Blocks for Product and Process Optimization

Artificial Intelligence – a big word. What lies behind it is often much easier to integrate into your established system than you may think. Especially in medium-sized businesses, as we know from our own experience. As a provider of ideas and as a technological as well as strategic partner, we support you in generating real added value through AI building blocks.

Where shall we start? Intelligently supplement instead of restructuring

The goal is to strengthen and expand your core competencies through artificial intelligence. In most cases the foundation already exists, usually in the form of rudimentarily used “data treasures”. When it comes to implementation, what is needed first is engineering expertise rather than a major investment turning half the company inside out.

At the start it is important to find out where previous solutions have reached their limits and where AI or machine learning can offer additional benefits. Such areas of application are usually found across the entire value chain. Where the greatest potential lies usually becomes clear in a direct exchange between your company's subject matter experts and our AI specialists. Once the goal has been determined, the actual project begins:

YOUR AI PROJECT IN 5 STEPS

- Data Review: First, we review the existing database. Often, this is already sufficient; if necessary, we can expand it with additional sensor technology, for example.

- Proof of Concept: In close cooperation with the business experts, an AI model is then developed, trained and optimized step by step.

- System Integration: The new AI module is designed to fit as seamlessly as possible into your established system architecture. Like an additional building block that enhances functionality.

- System or Process Optimization: AI unfolds its full potential in daily use under real conditions. It is constantly learning, improving and adapting to changing conditions.

- Monetization: The success of your AI project is reflected in figures.

Making smart use of existing "data treasures" - Our AI concepts in practice

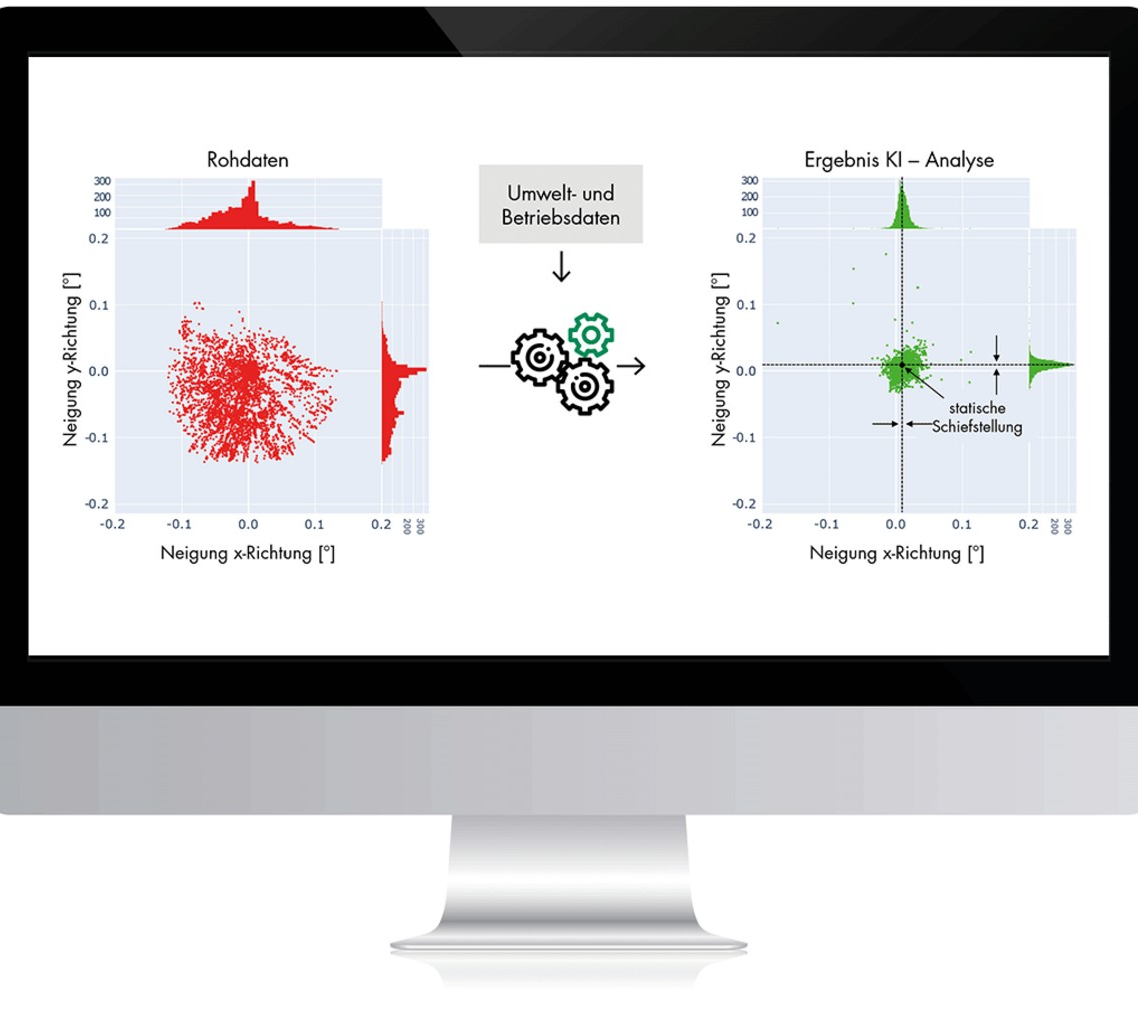

Wind Enegry-Structural Health Monitoring

Using AI, we innovatively optimized the functioning of our product SHM.Foundation and gained an advantage over our competitors. To do this, we used the existing sensor technology and database, which meant that no major investments or fundamental new developments were necessary. >> learn more

Rail - Predictive Maintenance

Freight or passenger cars are increasingly equipped with extensive sensor technology. We analyze the vibration data and use AI models in addition to classic, rule-based programming. For example, the recorded impact data can be traced back to its origin (classification) and the damage potential can be determined. The wagon can be serviced on time and a service life file can be created. We answer questions such as: Where and why did damage occur to my wagon? Where are the hotspots in my infrastructure? Where and why was my load damaged? >> learn more

Mechanical Engineering - Process Optimization

If mechanical and acoustic vibration signals are collected in addition to the process data already recorded, artificial intelligence can be used to reduce operating and maintenance costs and improve product and process quality. For example, an increased vibration level indicates increased wear, while noticeable acoustics are indicative of a faulty, recurring process (e.g., impact monitoring of a punch press). With learned AI models, even the smallest deviations are detected.

>> learn more